Energy transition and decarbonisation, an opportunity to seek sustainable industrial models.

One of humanity’s greatest challenges is the fight against climate change, global greenhouse gas (GHG) emissions need to reach a ceiling as soon as possible, but this implies carrying out a process of decarbonisation of current socio-economic systems and “transitioning” towards new efficient models in the use of resources, from raw materials to energy fluxes, based on clean and competitive energies. Genesal Energy is well aware of this.

How to perform the transition?

According to the Intergovernmental Panel on Climate Change (IPCC), it is not enough to replace current energy infrastructures, dependent on fossil fuels, with other renewable and sustainable ones. It is also necessary to implement energy efficiency measures which allow more than just reducing consumption. As is often said colloquially, “the best energy is the energy that is not consumed”.

In this context, the industrial sector must play an active role in the process of change. Genesal Energy is doing so: We have launched OGGY (Off Grid Genesal energY), our own energy management system that allows real-time monitoring of both production and energy consumption, deciding at all times what to do with these flows to make the most efficient use of them: store them in the battery system, consume them at the company’s facilities, discharge them into the grid or a combination of the previous options.

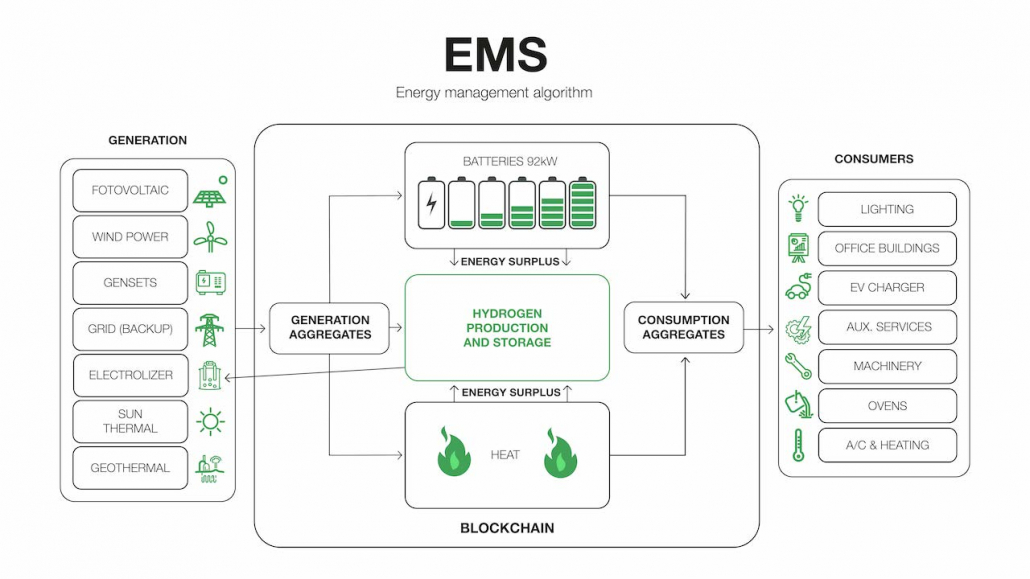

This system consists of three main blocks (Figure 1):

- The OGGY is capable of controlling different sources of energy generation, including the conventional electricity grid. In the specific case of the application at Genesal Energy, the sources are the following:

- Two photovoltaic building façades on our HQ warehouses (Illustration 2), which occupy a surface area of 111 m2. They are made up of 93 units of the latest generation crystal-silicon photovoltaic glass, with seven different sizes to suit the design of the original façade. In total, the installed power is 13.1kWp, which allows for a generation of 11 000 kWh per year. These panels are not installed on top of the old façade, they are integrated into it, allowing for better thermal insulation of the buildings.

- This means that we haven’t just focused on renewable self-consumption, but it has also been possible to reduce cooling needs by up to 50% reducing the air conditioning of the buildings. This installation alone – not mentioning the rest of the energy system – is going to avoid the emission of 245 tonnes of CO2 in 35 years, the equivalent of a saving of 661 barrels of oil per square metre.

- In addition to the façades, 126 photovoltaic panels with an output of 57.33 kW have also been installed on the roof of the company’s warehouses. These panels save more than 20 tonnes of CO2 per year.

- Testing of generators at the company’s facilities. All generators sold by Genesal Energy are tested at its facilities before being sent to the customer. This allows us to offer a top-quality warranty, but it also means consumption of fossil fuel. In accordance with the principles set out by the circular economy, the company has decided to reuse this energy by reintroducing it back into the value chain. The OGGY stores a percentage of the energy generated in these tests.

- Although the amount of energy generated in the facilities Genesal Energy could make us self-sufficient, we have maintained the connection to the conventional electricity grid in case of system failures.

- Two photovoltaic building façades on our HQ warehouses (Illustration 2), which occupy a surface area of 111 m2. They are made up of 93 units of the latest generation crystal-silicon photovoltaic glass, with seven different sizes to suit the design of the original façade. In total, the installed power is 13.1kWp, which allows for a generation of 11 000 kWh per year. These panels are not installed on top of the old façade, they are integrated into it, allowing for better thermal insulation of the buildings.

- The core, and the most important part, is the energy management algorithm or EMS, which is responsible for controlling all energy fluxes. This energy system continuously analyses the status of generation, storage and consumption in order to determine the system’s working profile at any given moment.

In addition, it considers variables external to the system, such as the weather forecast (to predict what the energy generated by the photovoltaic installation will be) or the price of electricity in real time (deciding whether to feed the energy into the grid or store it in the battery system).

In addition, it considers variables external to the system, such as the weather forecast (to predict what the energy generated by the photovoltaic installation will be) or the price of electricity in real time (deciding whether to feed the energy into the grid or store it in the battery system).

The integration between the OGGY system and the generating sources is performed through MODBUS, an open communication protocol used to transmit information through serial networks between different electronic devices. This is essential for the system to be able to properly manage all the fluxes and where they are directed to.

As for the storage system, it consists of a rack of lithium batteries with a total power of 92 kWh, grouped into 14 modules.

- Finally, there are the energy consumption points. In the case of Genesal Energy, these are the ones in the factory itself and the offices.

All Genesal’s actions, research and projects developed in the sustainability field are based on the absolute conviction that we are doing the right thing. The industrial sector must understand the processes of ecological transition and decarbonisation as opportunities to promote its own transformation towards sustainable models. Comprehensive energy management systems such as OGGY are key to this new scenario.

Antía Míguez, technologist at Genesal Energy