Is HVO this the fuel of the future?

Hydrogenated vegetable oil is making its way into the market due to its numerous properties and is one of the paths towards the energy transition.

Electricity is by no means the main form of energy used, nor is it easy to bring electrification to all sectors, and although it is true that the advance of renewable sources is remarkable, these days 80% of the world’s primary energy demand is still based on fossil fuels. An issue, not only because of the high levels of emissions and their consequences on climate change, but also because of the finite nature of these fuels.

Genesal Energy is very aware that it is urgent to find new sustainable fuels for those sectors where electrification is not going to happen overnight. HVO enters the scene, which in recent years has been positioning itself as one of the main alternatives to diesel. We give you all the keys to this new fuel.

What is HVO?

Hydrogenated Vegetable Oil (HVO) is a second-generation biofuel. Although it has the words “vegetable oil” in its name, it can be produced from a variety of vegetable and non-vegetable sources:

- Used vegetable cooking oil (UCO, Used Cooking Oil).

- Waste animal fat.

- Tall oil, a by-product of wood pulp manufacture.

- Non-food grade vegetable oils (rapeseed, soybean and palm).

On their own, these oils are not effective fuels. However, through a process known as hydrotreating, it is possible to convert the fats in these oils into hydrocarbons almost identical to conventional diesel.

Is it the same as biodiesel?

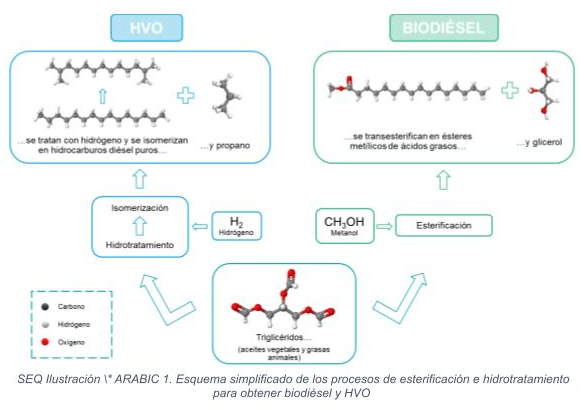

No, biodiesel and HVO are different fuels. While both are based on triglycerides from vegetable oils and animal fats, biodiesel is made by esterification: the oily source is treated with an alcohol, usually methanol, and a catalyst. This produces glycerine and a fuel made from fatty acid methyl esters or FAME (Fatty Acid Methyl Ester).

On the other hand, to obtain HVO, the oils are subjected to a hydrotreating process. Simply put, hydrogen is used to remove oxygen from the oil at high temperatures, splitting the fat molecules into separate chains of hydrocarbon molecules. The result is a stable fuel comparable to fossil diesel in both form and performance, making HVO superior to biodiesel as an alternative to fossil fuel.

What are the advantages of using HVO?

They include the following:

- -If waste oils are used as source, and produced relatively locally, the use of HVO can result in a reduction of CO2e emissions by up to 90%.

- When burning HVO, emissions of carbon monoxide (COx) and other polluting particles are lower.

- Its service life is long: up to ten times longer than diesel.

- Its performance is maintained even at extreme temperatures (-30°C).

- It has good chemical characteristics. It is aromatic, low density, with a very high cetane number and no sulphur. In addition, its calorific value, and therefore its energy content, is higher than that of biodiesel.

- Unlike biodiesel, which needs to be blended with conventional diesel to work properly, HVO is a direct fuel, which can be completely replaced in most diesel units.

- Also in comparison, biodiesel is prone to degradation and needs very specific planning for storage. Only a single oil tank is needed to store HVO. In fact, conventional diesel tanks can be filled with HVO, and vice versa, so that if, for example, we are running on HVO, but it runs out and it is impossible to procure it quickly enough, we can switch back to diesel.

Different brands in the combustion engines and distributed energy worlds have already started to echo the benefits of HVO, certifying that their products are compatible with this biofuel.

For example, several companies have declared that all their Euro 5 and Euro 6 engines are compatible with the use of HVO.

Is HVO sustainable?

Speaking of sustainability we must pay attention not only to its properties, but also to its entire value chain. Are the source and production relatively local? Regarding the origin of the source, are only waste oils used, or do they also include, for example, oil crops? Have changes in land use been necessary to make such crops available? If we look at the whole picture, to speak of a 100% HVO we need to be sure that it is produced from a source derived from real waste and that environmental and social criteria are respected along the whole value chain.

And another question arises: If we have available an HVO that we know is not 100% sustainable… Is it better to use it or to continue using fossil diesel? Do we look for an alternative, such as another type of biofuel or even a synthetic fuel? These are difficult questions to answer that depend on many factors.

The Greenesal Scale

In order to facilitate decision making on the choice and use of fuels, Genesal Energy has created the “Greenesal Sustainability Assessment Scale for Fuels”.

It is a tool that will allow us to evaluate the sustainability of fuels, so that it is not only easier to choose between the different options available, but it will also provide a clear idea of the real impact of each one of them. In addition, the tool will fairly weight factors related to the three spheres of the sustainable development:

- Environmental sphere: raw material origin, GHG emissions, soil organic carbon, eutrophication, acidification, energy balance, biodiversity.

- Economic sphere: capital costs, operational costs.

- Social sphere: land rights, issues related to working conditions, relationship with local communities.

In this way, not only will it be possible to distinguish between different types of fuel, but it will also be possible to know which has a greater positive impact on the search for a sustainable future.