Energy alternatives for a decarbonised future: the role of hydrogen

In recent decades, the growing dependence of our economy on fossil fuels has aggravated both environmental and economic challenges due to a combination of two factors: the growth in energy demand and the progressive depletion of fossil fuel reserves. This scenario has created significant tensions in the energy supply chain, highlighting the urgent need to find sustainable alternatives. As a response, recent R&D&I efforts have increasingly focused on the decarbonisation.

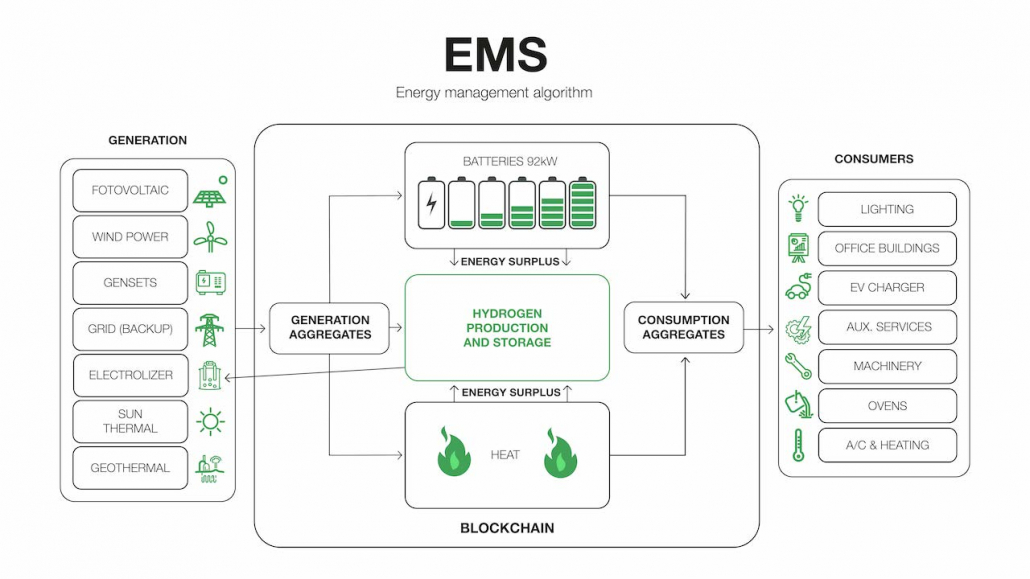

However, for decarbonisation to be truly efficient, it is necessary to understand that the new energy system must be made up of a combination of technologies both being capable of satisfying the growing energy demand and being sustainable. Hydrogen enters the picture as a key energy vector – both at industrial and domestic level – with potential to transform the global energy landscape.

Hydrogen: the energy wildcard of the future

One of the features that make hydrogen a great alternative is that it can be produced by renewable energies through electrolysis. This technology makes it possible to convert the energy surpluses produced during peaks of renewable generation – when there is an abundance of sun or wind – into hydrogen, a clean energy and versatile energy carrier. Moreover, hydrogen can be stored for long periods and then be converted both into electricity – using fuel cells or generators – or into heat, using boilers.

In addition to its storage capacity, hydrogen also offers flexibility in terms of transport. It can be distributed through a pipeline network similar to that used for natural gas, although local or decentralised production is also feasible, which significantly reduces transport costs. Such decentralisation would enhance the sustainability and self-sufficiency of the developed electricity system, increasing storage capacity and providing greater flexibility and availability of clean energy.

Hydrogen also plays a key role in the current and future chemical industry, being a valuable resource in processes such as the production of gasoline and other petroleum derivatives. In the future, it will be fundamental in the creation of synthetic fuels from CO2, which will contribute significantly to reducing the carbon footprint of these fuels.

These include alkaline electrolysis, one of the oldest technologies; proton exchange membrane electrolysis (PEM) – whose development has accelerated in the last decade – and solid oxide electrolysis (SOEC) – which is under development and is prominent in industries with surplus heat.

The true colours of H2

The path towards decarbonisation cannot afford to get rid of fossil fuels immediately. It requires a planned and gradual approach that considers environmental impact. While hydrogen production through renewable energy is the most sustainable and preferred option in the long term, other technologies still play an important role in this process. These technologies, which allow hydrogen to be produced from different sources, have led to the classification of hydrogen into different ‘colours’, depending on the raw materials used and the production methods applied.

-

- Golden hydrogen refers to hydrogen that existed already on Earth, in underground deposits, and does not require industrial processes to obtain it.

- Brown hydrogen comes from coal gasification, a process with high carbon emissions.

- Grey hydrogen, produced from natural gas, also emits large amounts of CO2 during its production. It’s currently one of the most common.

- Blue hydrogen is produced in a similar way to grey hydrogen, but includes carbon capture and storage systems (CCS), which significantly reduces pollutant emissions.

- Pink hydrogen is produced using nuclear-generated electricity, which, although low in emissions, raises debate over nuclear waste.

- Yellow hydrogen refers to hydrogen produced using electricity from an energy mix that can include both renewable and non-renewable sources, which generates a medium environmental impact.

- Green hydrogen, considered the most sustainable, is generated from renewable energy sources, such as solar or wind power, ensuring a zero-carbon production process.

By establishing these categories, a better understanding of the environmental footprint and the advantages or disadvantages of each type of hydrogen is facilitated, which is crucial for the design of energy policies and for guiding investment decisions towards cleaner technologies.

The technological evolution behind green hydrogen

The growth of renewable energy has driven the development of water electrolysis as one of the main technologies for producing green hydrogen. This process uses clean energy – such as solar or wind power – to split the water molecule into hydrogen and oxygen. Currently, there are three commercial electrolysis technologies operating and another one in development:

-

-

- Alkaline electrolysis. It uses a basic medium and operates at temperatures close to 80ºC and at atmospheric pressure (1.01325 bar), although it is possible to work with up to 30 bar. Low current densities are used, which implies a lower production per occupied surface area, but high efficiencies are achieved, close to 70%. Abundant materials such as steel or nickel can be used for their construction.

-

-

-

- PEM (polymeric proton membrane) electrolysis. It uses an acid medium and operates at temperatures close to 60ºC and pressures above 30 bar. High current densities are used, allowing for very compact equipment, but the efficiency is slightly lower. Rare metals are used in their construction, which makes the equipment more expensive.

- SOEC (solid oxide electrolysis cell). It is a solid electrolyte which uses water at very high temperatures – around 800ºC – and atmospheric pressure. The current density used is somewhat lower than that used in PEM electrolysers, resulting in compact equipment and efficiencies of up to 80%. They require an external supply of energy in the form of heat though. The materials used are more expensive because they must withstand the high temperatures.

- AEM (anion exchange membrane) electrolysis. It combines the best of PEM & Alkaline technologies obtaining high current densities and an average efficiency between the two variants. However, current equipment is not yet at the level of development needed to be competitive. While the necessary materials are abundant, the problem lies in the membrane, for which a suitable material has not yet been developed.

-

Pioneers in hydrogen: genesal energy bets for the change

Genesal Energy is actually committed to hydrogen. We are developing our own electrolyser with the aim of acquiring experience in this technology. It’s called the H2OG project. In the medium term, this knowledge will allow us to optimally integrate this energy vector in our machinery, not only in the generator sets, but also in the management and storage systems.

The development of this project began with the design of a small-scale electrolyser, which allows us to validate its operation and guarantee the expected results. This planning is key before building the final, larger equipment, as it allows solving possible design flaws before the final integration into the production system, which translates into lower costs.

If you want to know more about the project, watch the following video, in which Guillermo Martínez, Chemical Engineer, explains more about the subject.